Professional manufacturer of vertical & horizontal wind turbine generator, PMG generator

info@engelec.cn

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

EN-300W-M

ENGELEC

EN-300W-M

| Availability: | |

|---|---|

EN-300W-M Horizontal Axis Wind Turbine 300W

Overview

Special-shaped magnet and unique winding structure, low starting wind speed, can be started at 2m/s(5 blades 1.5m/s) without any auxiliary starting device

Nylon fiber blades and reasonable pneumatic appearance, so that the whole machine runs with low noise.

Using rare earth permanent magnet to reduce the volume and weight of the whole machine.

Extremely high power efficiency, 100% full output power.

Moulded whole machine, ensured the consistent quality of the products

With over-voltage, over-discharge, over-current, automaticaly protection at strong wind.

Die-casting aluminum case with corrosion resistance performance.

Strictly sealed, sand, salt spray, rainwater can't invade the inside of the motor

Unique heat dissipation structure to ensure the design life of the machine is 15-20 years.

Application

The EN-300W-M wind turbine is widely used in LED light, street signal & camera security, outdoor telecommunication system and off-grid residence.

The EN-300W-M wind turbine is extremely easy to integrate with solar panels to consist a wind & solar hybrid off-grid power systems for consistent and clean energy. Available in 12V, 24V for battery charging.

Advantage

Low starting wind speed, compact, light, beautiful and with little vibration.

Easy installation

Blades color can be customized to country flag, company logo and etc.

Permanent magnetic with special stator, effectively reduce torque to be only 1/3 of ordinary generator for more excellent performance.

Specification sheet

| Model | EN-300W-M | EN-400W-M |

| Rated power | 300W | 400W |

| Max power | 320W | 410W |

| Nominal voltage | 12V/24V | 12V/24V |

| Start-up wind speed | 2.0m/s | 2.0m/s |

| Rated wind speed | 11m/s | 11.5m/s |

| Survival wind speed | 50m/s | 50m/s |

| Top net weight | 9.2kg | 9.5kg |

| Wind wheel diameter | 1.35m | 1.55m |

| Number of blades | 3/5pcs | |

| Blades material | Nylon Fiber | |

| Generator | Three phase ac permanent magnet generator | |

| Controller system | Electromagnetic | |

| Speed regulation | The wind Angle automatically | |

| Working temperature | -40℃~80℃ | |

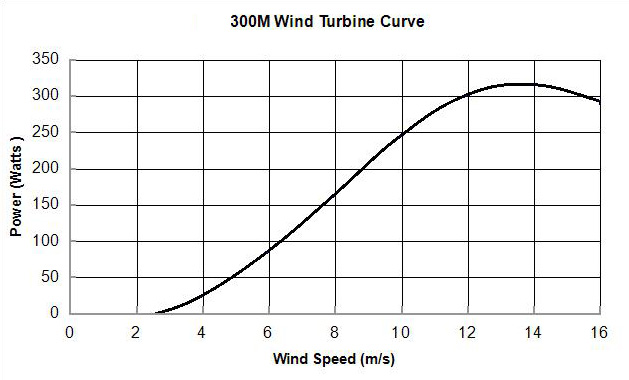

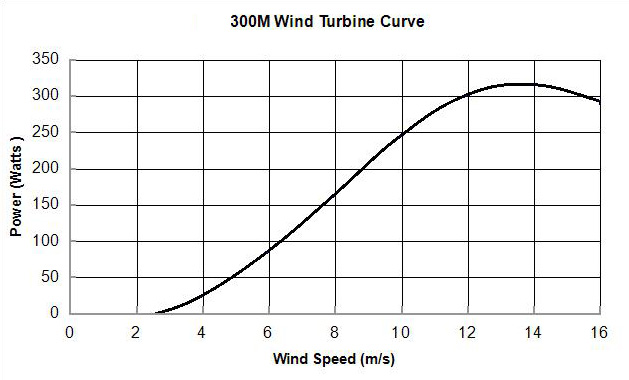

EN-300W-M Wind turbine Power Curve Test

We as the most professional supplier and manufacturer of wind turbines, we can accept one piece & instant delivery to any place in the world.

Our clients can choose the delivery service

by expresss

by air

by sea

by truck.

A: Our small wind turbine is very convenient and easy to install. It is fixed by the flange and bolts to the base. we will offer the installation manual with the goods together, you can finish installtion within 3 minutes by following the manual.

When installation, you'd better choose the flat and open area. We recommend the installation height should be at least 6m above ground, because higher area has stronger wind and steadier airflow. If installed on the roof top, it's better has 5m space to the obstacles. The trees and buildings can block airflow. The obstacles create a slow and turbulent airflow area in front of and behind them, where it should be avoided to install the wind turbine.

A: We use aluminum alloy material for the generator shell and blades, compared with other cast iron products, our products are light in weight, good in balance, and the power output is more stable. Our turbine blades design has the best fatigue strength and mechanical properties, can withstand the extremely severe conditions of storms and random loads. The turbine surface is smooth to reduce wind drag, the surface coating will resistant to corrosion and strong sunlight.

A: Our wind turbines uses a three-phase permanent magnet synchronous generator. Its advantages is simple structure, small volume, light weight, small loss, high efficiency and high power factor. It is mainly used for high performance servo drive systems and DC generator replacement where require a quick and precise correspond and wide speed range.

A: 1. Check the stay wires of the supporting pole, if it is loose, you should tighten it in time. Multiple checkings should be repeated during the first months after installation. The stay wires should also be checked after very strong wind.

2. Check and secure that the connection point in the electrcity circuit are secured well.

3. Regular checking and maintenance for the batteries.

4. Fix the supporting pole more firmly or put down it before severe weather coming such as hurricanes.

EN-300W-M Horizontal Axis Wind Turbine 300W

Overview

Special-shaped magnet and unique winding structure, low starting wind speed, can be started at 2m/s(5 blades 1.5m/s) without any auxiliary starting device

Nylon fiber blades and reasonable pneumatic appearance, so that the whole machine runs with low noise.

Using rare earth permanent magnet to reduce the volume and weight of the whole machine.

Extremely high power efficiency, 100% full output power.

Moulded whole machine, ensured the consistent quality of the products

With over-voltage, over-discharge, over-current, automaticaly protection at strong wind.

Die-casting aluminum case with corrosion resistance performance.

Strictly sealed, sand, salt spray, rainwater can't invade the inside of the motor

Unique heat dissipation structure to ensure the design life of the machine is 15-20 years.

Application

The EN-300W-M wind turbine is widely used in LED light, street signal & camera security, outdoor telecommunication system and off-grid residence.

The EN-300W-M wind turbine is extremely easy to integrate with solar panels to consist a wind & solar hybrid off-grid power systems for consistent and clean energy. Available in 12V, 24V for battery charging.

Advantage

Low starting wind speed, compact, light, beautiful and with little vibration.

Easy installation

Blades color can be customized to country flag, company logo and etc.

Permanent magnetic with special stator, effectively reduce torque to be only 1/3 of ordinary generator for more excellent performance.

Specification sheet

| Model | EN-300W-M | EN-400W-M |

| Rated power | 300W | 400W |

| Max power | 320W | 410W |

| Nominal voltage | 12V/24V | 12V/24V |

| Start-up wind speed | 2.0m/s | 2.0m/s |

| Rated wind speed | 11m/s | 11.5m/s |

| Survival wind speed | 50m/s | 50m/s |

| Top net weight | 9.2kg | 9.5kg |

| Wind wheel diameter | 1.35m | 1.55m |

| Number of blades | 3/5pcs | |

| Blades material | Nylon Fiber | |

| Generator | Three phase ac permanent magnet generator | |

| Controller system | Electromagnetic | |

| Speed regulation | The wind Angle automatically | |

| Working temperature | -40℃~80℃ | |

EN-300W-M Wind turbine Power Curve Test

We as the most professional supplier and manufacturer of wind turbines, we can accept one piece & instant delivery to any place in the world.

Our clients can choose the delivery service

by expresss

by air

by sea

by truck.

A: Our small wind turbine is very convenient and easy to install. It is fixed by the flange and bolts to the base. we will offer the installation manual with the goods together, you can finish installtion within 3 minutes by following the manual.

When installation, you'd better choose the flat and open area. We recommend the installation height should be at least 6m above ground, because higher area has stronger wind and steadier airflow. If installed on the roof top, it's better has 5m space to the obstacles. The trees and buildings can block airflow. The obstacles create a slow and turbulent airflow area in front of and behind them, where it should be avoided to install the wind turbine.

A: We use aluminum alloy material for the generator shell and blades, compared with other cast iron products, our products are light in weight, good in balance, and the power output is more stable. Our turbine blades design has the best fatigue strength and mechanical properties, can withstand the extremely severe conditions of storms and random loads. The turbine surface is smooth to reduce wind drag, the surface coating will resistant to corrosion and strong sunlight.

A: Our wind turbines uses a three-phase permanent magnet synchronous generator. Its advantages is simple structure, small volume, light weight, small loss, high efficiency and high power factor. It is mainly used for high performance servo drive systems and DC generator replacement where require a quick and precise correspond and wide speed range.

A: 1. Check the stay wires of the supporting pole, if it is loose, you should tighten it in time. Multiple checkings should be repeated during the first months after installation. The stay wires should also be checked after very strong wind.

2. Check and secure that the connection point in the electrcity circuit are secured well.

3. Regular checking and maintenance for the batteries.

4. Fix the supporting pole more firmly or put down it before severe weather coming such as hurricanes.